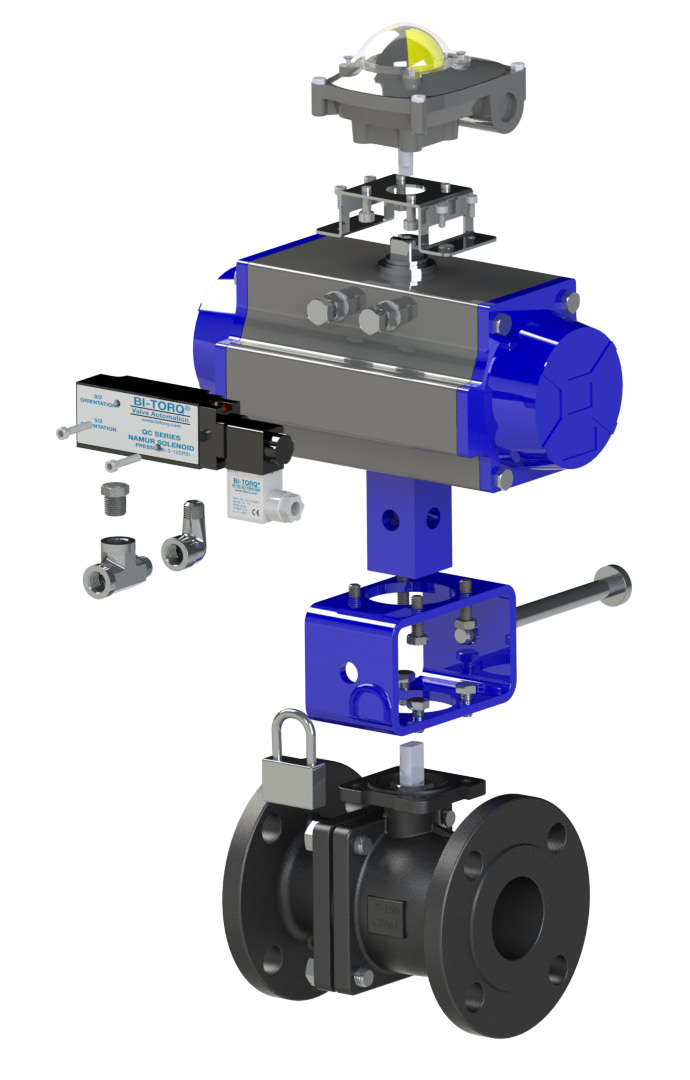

Valve operators run many risks. There is always the risk of explosion, exposure to high-pressure steam, combustion gasses, and other harmful chemicals. CBT partner, BI-TORQ Valve Automation’s, lockout device for automated quarter-turn valves prevents accidentally opening or closing of a critical shut-off device from a remote location like a PLC. The valve can be locked out in either the open or closed position, allowing maintenance personnel to work on other parts of the system without concern that the valve will accidentally be opened. The most common assembly features a heavy-duty lockout pin and a convenient storage device built in to the bracket so the pin does not get lost. BI-TORQ can custom fit this lockout device on any quarter turn ball, butterfly or plug valve mounted to any pneumatic or electric actuator.

Valve operators run many risks. There is always the risk of explosion, exposure to high-pressure steam, combustion gasses, and other harmful chemicals. CBT partner, BI-TORQ Valve Automation’s, lockout device for automated quarter-turn valves prevents accidentally opening or closing of a critical shut-off device from a remote location like a PLC. The valve can be locked out in either the open or closed position, allowing maintenance personnel to work on other parts of the system without concern that the valve will accidentally be opened. The most common assembly features a heavy-duty lockout pin and a convenient storage device built in to the bracket so the pin does not get lost. BI-TORQ can custom fit this lockout device on any quarter turn ball, butterfly or plug valve mounted to any pneumatic or electric actuator.

KEY FEATURES

- Universal design for lockout in open and/or close positions

- Designed to OSHA standards

- Protects personnel and product in critical applications

- Carbon steel or stainless steel construction

- Heavy-duty lock-out pin

- Convenient storage

- Standard padlock

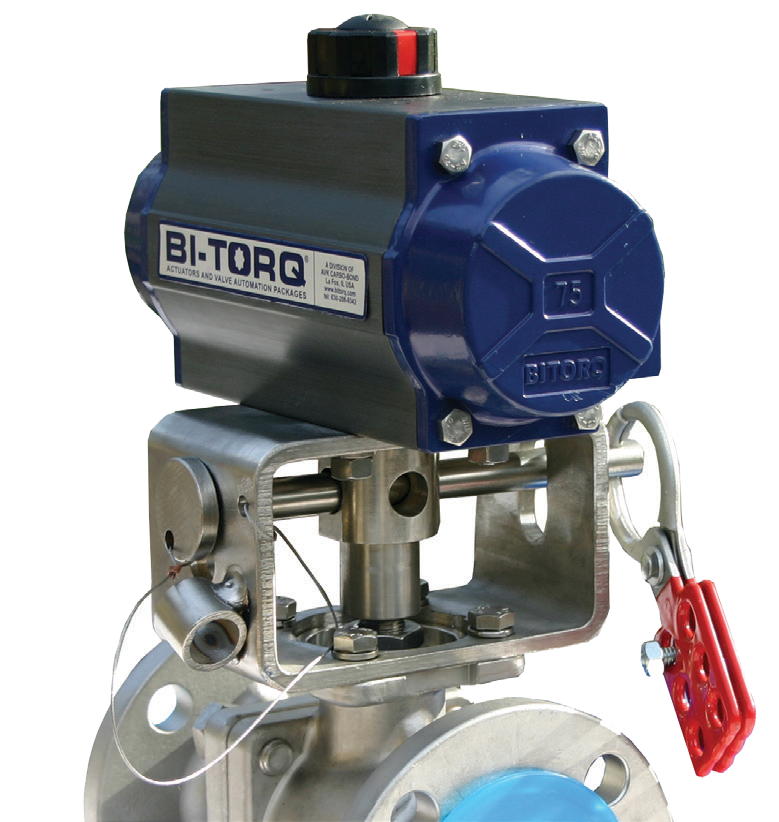

The unit shown to the left was designed as part of a system for processing titanium. The flanged valve was installed at the beginning of a critical process line and required a lockout in the closed position so that the valve could not be accidentally opened while personnel maintained other system components. This also helped prevent the loss of any material in the pipeline due to improper actuation. A limit switch was added later so that plant personnel could see if the valve was in the correct position prior to lock-out. For more information on BI-TORQ lockout devices, contact your CBT specialist today.

The unit shown to the left was designed as part of a system for processing titanium. The flanged valve was installed at the beginning of a critical process line and required a lockout in the closed position so that the valve could not be accidentally opened while personnel maintained other system components. This also helped prevent the loss of any material in the pipeline due to improper actuation. A limit switch was added later so that plant personnel could see if the valve was in the correct position prior to lock-out. For more information on BI-TORQ lockout devices, contact your CBT specialist today.