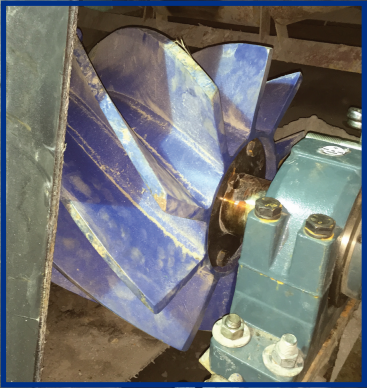

Martin Sprocket & Gear’s Pulley Division has recently introduced the new Clean Flight Wing (CFW) Pulley. The Clean Flight Wing Pulley merges the existing technology from Martin’s well-known product groups; the pulley and screw conveyor. Each CFW Pulley is manufactured with precision cut flights, similar to those used in the conveyor and heavy-duty flat pulley core. The design features of the Clean Flight Wing Pulley provides extreme duty flight materials (1/2″, 3/4″, and 1″ thick), continuous weldment on each flight, no contact bars, and improved concentricity. The CFW Pulley reduces vibrations, decreases noise, provides belt cleaning and tracking, and improves material rejection – maximizing ease of installation.

Martin Sprocket & Gear’s Pulley Division has recently introduced the new Clean Flight Wing (CFW) Pulley. The Clean Flight Wing Pulley merges the existing technology from Martin’s well-known product groups; the pulley and screw conveyor. Each CFW Pulley is manufactured with precision cut flights, similar to those used in the conveyor and heavy-duty flat pulley core. The design features of the Clean Flight Wing Pulley provides extreme duty flight materials (1/2″, 3/4″, and 1″ thick), continuous weldment on each flight, no contact bars, and improved concentricity. The CFW Pulley reduces vibrations, decreases noise, provides belt cleaning and tracking, and improves material rejection – maximizing ease of installation.

Martin Clean Flight Wing Pulley Distinct Construction Advantages:

- Each flight lies perpendicular to the pulley core, resulting in a much stronger design

- The CFW is constructed with distinctly aggressive materials with thick flights

- Continuous welds available upon request

- An open herringbone flight placement allows for better material rejection

Noise Reduction: -Users report a reduction in operating decibels from 14-22%, depending on belt speed and belt width Less Vibration in Operation: -Since the belt is in constant contact with the CFW outside diameter, the “belt-slapping” observed in traditional wing pulley operation is eliminated, as is the operational ambient noise. Decreased vibration also means less stress on the belt, splice, and bearings.

Noise Reduction: -Users report a reduction in operating decibels from 14-22%, depending on belt speed and belt width Less Vibration in Operation: -Since the belt is in constant contact with the CFW outside diameter, the “belt-slapping” observed in traditional wing pulley operation is eliminated, as is the operational ambient noise. Decreased vibration also means less stress on the belt, splice, and bearings.

Enhanced Belt Tracking -Each CFW flight contacts the belt at a helix angle that contributes tot he tracking of the belt. The CFW flight operates much like a traditional “spiral” wing pulley in assisting belt tracking. The Martin CFW is also offered a crown-face profile.

Optimized Belt Cleaning-As well as reducing vibration noise and improving belt tracking, the CFW also cleans the belt more effectively while in operation by shedding materials away from the belt surface. Additionally, the CFW operates with less vibration at the skirt board zones, reducing fines at the loading zone.

Improved Material Rejection -Traditional wing pulley flights contact the conveyed material at a right angle, whereas the CFW actually “plows” material out of harm’s way, toward the end of the pulley, where it safely falls away from the pulley and belt contact surface. Martin is CBT Supplier Spotlight for the month of February. For more information, contact your CBT specialist today.