The Challenge

The exhaust gas fan failed in the processing facility of a globally-active specialty chemicals company. The plant operator was forced to replace the rolling bearings quickly due to the toxic gases and the resulting explosive atmosphere that occurred in the chemical production process. However, it was very difficult to access the standard spherical roller bearing, with which the fan was originally fitted. Experience had shown that a mounting time of approximately 14 hours had to be expected in such cases.

Schaeffler Solution

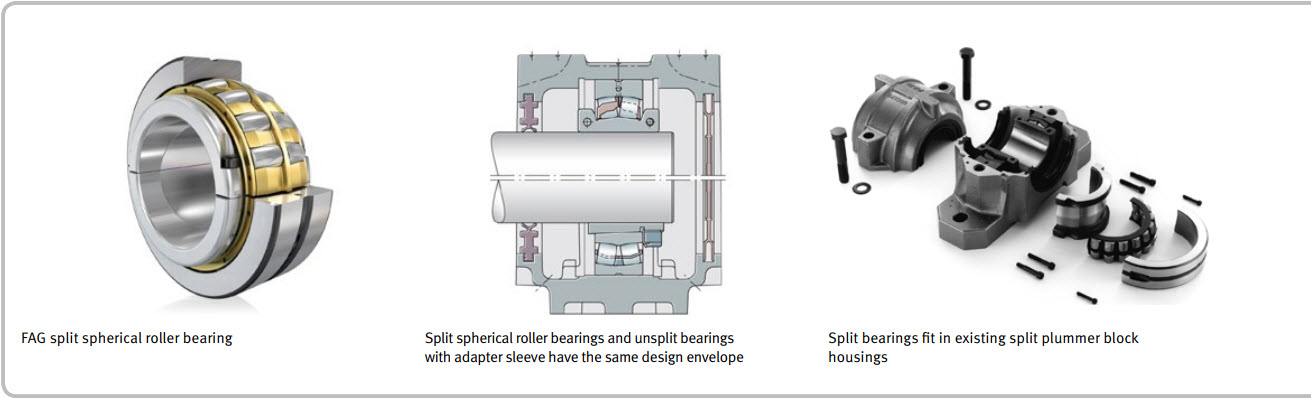

In order to achieve optimum downtime periods and costs, Schaeffler recommended using a FAG split spherical roller bearing. These bearings can be fitted as a direct replacement for conventional spherical roller bearings and the corresponding adapter sleeve; the outside diameter, outer ring width and diameter of the shaft sear are the same. Schaeffler also provided the customer with support during mounting. All detailed planning work was coordinated in close collaboration with Schaeffler-mounting specialists as well as Schaeffler application engineers. An experienced Shaeffler technician assisted with the mounting and modification work on site.

Customer Benefit

Downtimes during bearing replacement and fitting costs were significantly reduced due to the change from a standard spherical roller bearing to an FAG split spherical roller bearing.

| Costs | Unsplit bearing | Split bearing |

| Downtime | 14 hours | 3 hours |

| Costs of production stoppage ($23,656 per hour during stoppage of the fan) | $331,600 | $71,057 |

| Man Hours | $3117 | $668 |

| Alignment | $604 | not required |

| Crane Hire | $473 | not required |

| Replacement bearing (drive side, as a precaution) | $390 | not required |

| Replacement bearing (fan side) | $390 | $850 |

| Total costs for bearing replacement | $336,574 | $72,575 |

| Cost Savings: | $263,999 | |

What’s Special

In addition to the direct savings, the use of FAG split spherical roller bearings also makes long-term savings possible, as future bearing replacements can be carried out more quickly. The benefits in terms of costs and time listed above can be achieved from the very beginning if split bearings are considered from the start when designing new plants and machinery. Schaeffler is featured as CBT’s Supplier Spotlight for the month of December. Contact your CBT specialist today for more information.