Intralox SeamFree Belting

Intralox SeamFree belting is specially designed to help processors reduce sanitation times, water usage, and manual labor needs. The absence of bricklayed seams across the width of the belt, combined with its non-porous, nonabsorbent plastic material, serve to decrease contamination risks and promote top-of-the-line food safety.

By eliminating vertical or bricklayed seams across the width of the belt, SeamFree belts decrease contamination and bacterial harborage risks. SeamFree belts are available in two models: Series 850 SeamFree Minimum Hinge Flat Top Belt pitch: 2.0 in (50.8 mm) Maximum module width: 36 in (914 mm) Series1650 SeamFree Minimum Hinge Flat Top Belt pitch: 1.0 in (25.4 mm) Maximum module width: 18 in (457 mm)

By eliminating vertical or bricklayed seams across the width of the belt, SeamFree belts decrease contamination and bacterial harborage risks. SeamFree belts are available in two models: Series 850 SeamFree Minimum Hinge Flat Top Belt pitch: 2.0 in (50.8 mm) Maximum module width: 36 in (914 mm) Series1650 SeamFree Minimum Hinge Flat Top Belt pitch: 1.0 in (25.4 mm) Maximum module width: 18 in (457 mm)

An Easy Retrofit Option

- SeamFree belts can be easily retrofitted onto conveyors currently running Intralox Series 800 or 1600 belts

- No need to change sprockets—SeamFree belts can run on existing Series 800 or 1600 sprockets

- Cost-effective SeamFree belts offer greater benefits than the belts they replace for the same price

- Immediately improves and eases sanitation and maintenance

Designed With Sanitation In Mind

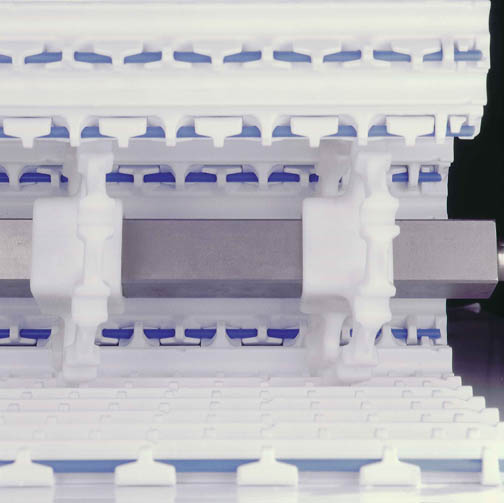

The SeamFree belt’s unique design features ensure consistent, effective cleaning results with minimized debris trapping:

- Patented flume design channels water and debris to belt edge for easy cleaning

- Drive bar mechanism prevents sprockets from pressing debris into hinges

- Cam-link hinges increase rod exposure to prevent debris clogging

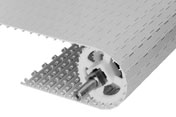

EZ Clean Angled Sprockets

Intralox EZ Clean Angled sprockets are available in either Series 800 (for the Series 850 SeamFree belt) or Series 1600 (Series 1650 belt). SeamFree belts utilize a unique sprocket design to further enhance sanitation efficiency. Intralox EZ Clean Angled sprockets allow access to 100% of the critical belt underside to ensure that all parts of the belt can be cleaned.

Intralox EZ Clean Angled sprockets are available in either Series 800 (for the Series 850 SeamFree belt) or Series 1600 (Series 1650 belt). SeamFree belts utilize a unique sprocket design to further enhance sanitation efficiency. Intralox EZ Clean Angled sprockets allow access to 100% of the critical belt underside to ensure that all parts of the belt can be cleaned.

A Food Safe Solution

Intralox SeamFree belting is an ideal solution for a wide variety of food-processing industries, including:

- Meat

- Poultry

- Seafood

- Fruit and Vegetable

- Snack

- Ready-to-Eat Meals

About Intralox

The inventors of modular plastic belting, Intralox has more than 40 years’ experience manufacturing hygienic belting solutions for food processors. Intralox technologies reduce product loss, maintenance costs, and belt wear (from corrosion or abrasion) to enable better sanitation and enhanced hygienic performance in food-contact applications. Intralox is the CBT Vendor of the Month for November. For more information, please contact your CBT specialist.